Experiment → 2 - B2

2 - B2

Output

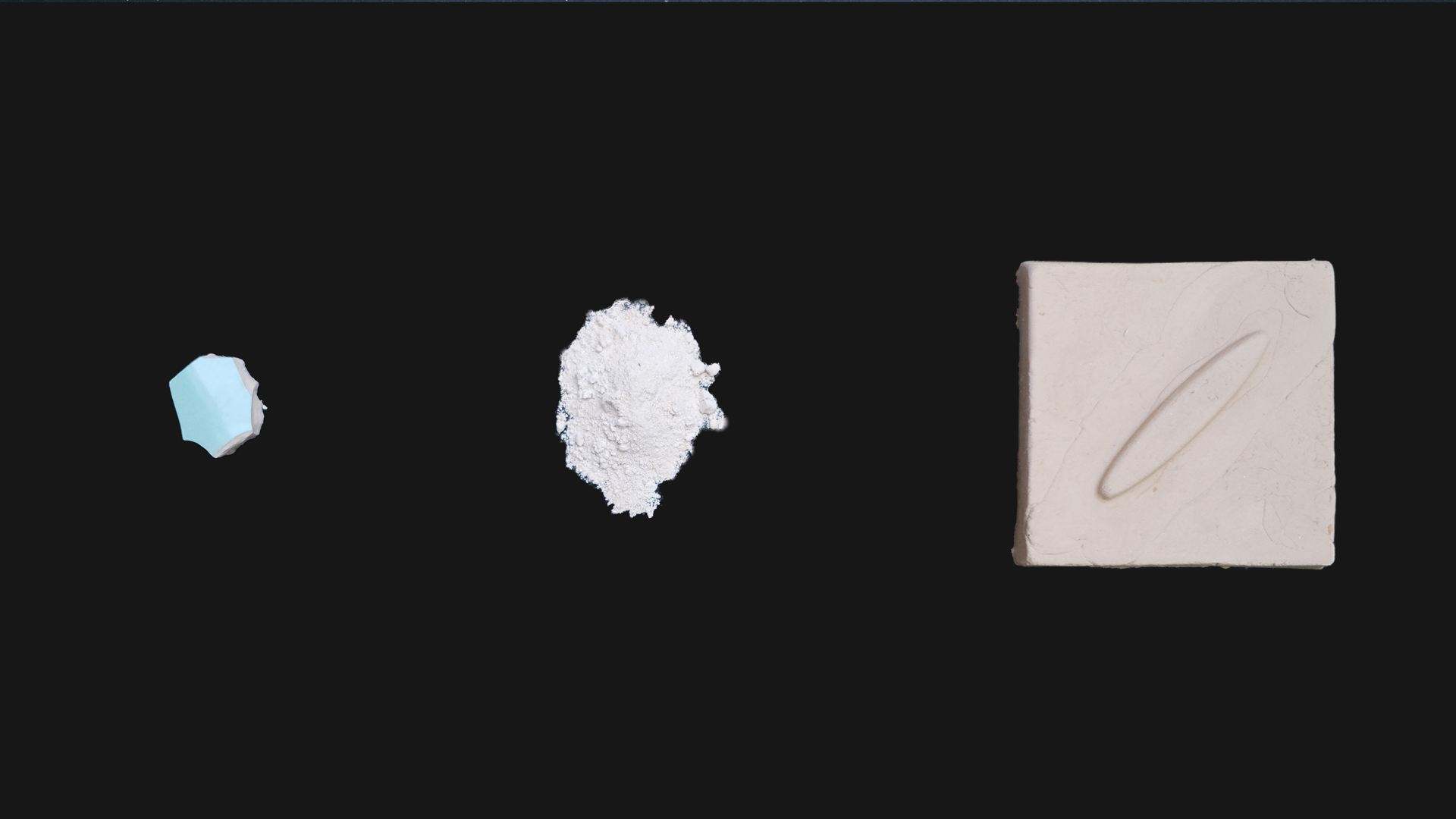

Sample tile made of 70% stoneware with 30% recycled stoneware residues from industrial throw-outs of the ceramic factory of GRESTEL. Plates made of stoneware with a light green glazing, unfortunatley with production defects, which would go to the trash.

This material samples contain a percentage of 30% of broken plates grinded into a fine waste ceramic powder and mixed within the liquid clay.

specs

Production Process:

• waste collection

• manual shredding process with a hammer to destroy the object into smaller pieces

• ceramic shredder (jaw crusher and than hammer mill machine) at CICECO - Aveiro Institute of Materials

• Portioning 100ml of ceramic clay with a composition of 30% waste powder and 70% liquid raw material and additional 5-10% water if necessary

• slip casting mould

• drying phase

Firing:

• bisque firing - low firing with temperature of 950℃

• second firing - high firing with temperature of 1200℃

Reference:

2 - B2

2 (70%) - stoneware

B2 (30%) - fired and glazed stoneware