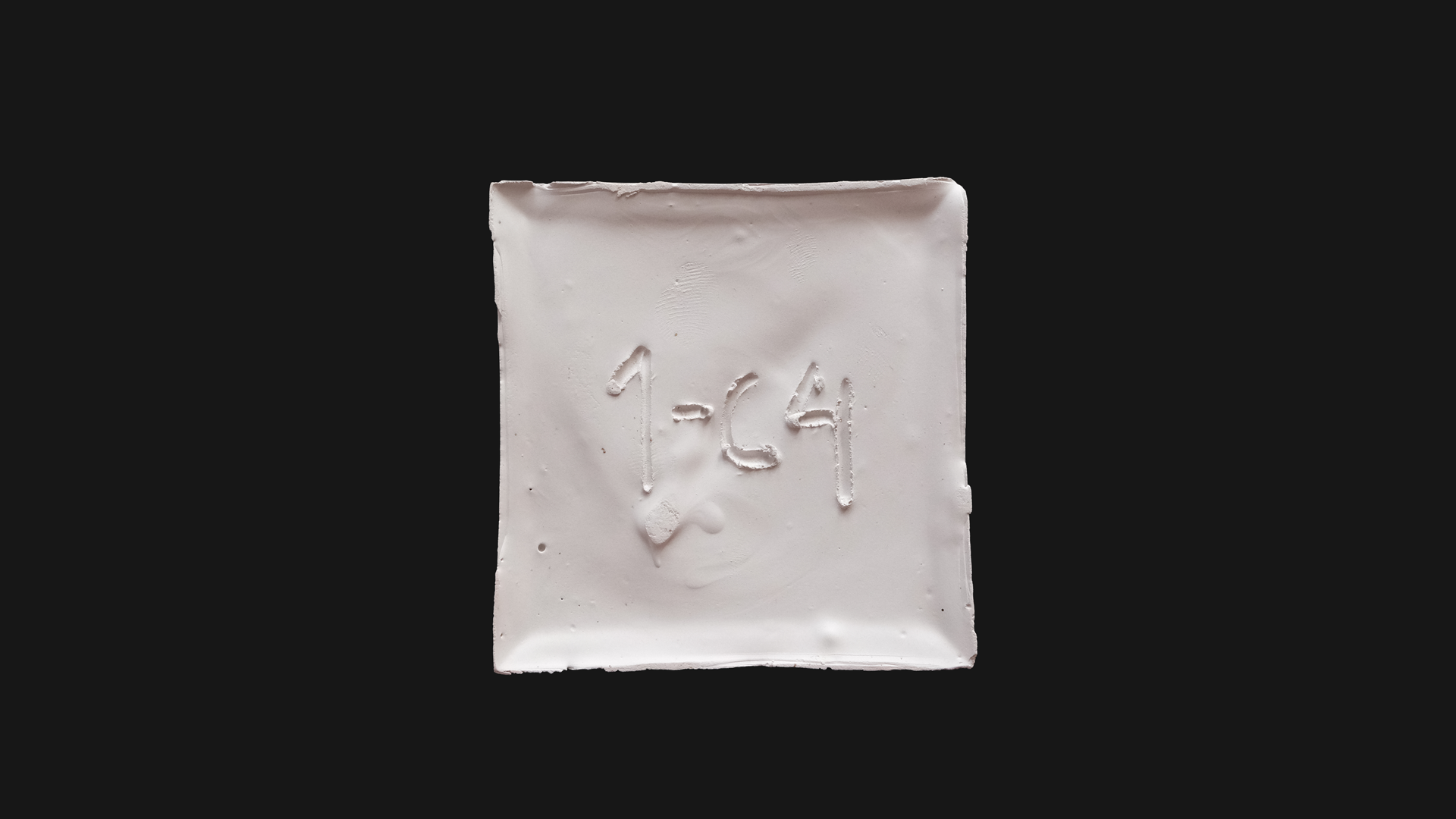

Experiment → 1-C4

1-C4

Output

Composition:

70% porcelain with 30% recycled waste aggregates.

This material sample contains a percentage of 30% of ceramic dust particles filtered out of the air from the industrial production side from the company GRESTEL - a Portuguese company dedicated to manufacturing and designing tableware and accessories made of fine stoneware, located at Vagos, Aveiro district.

specs

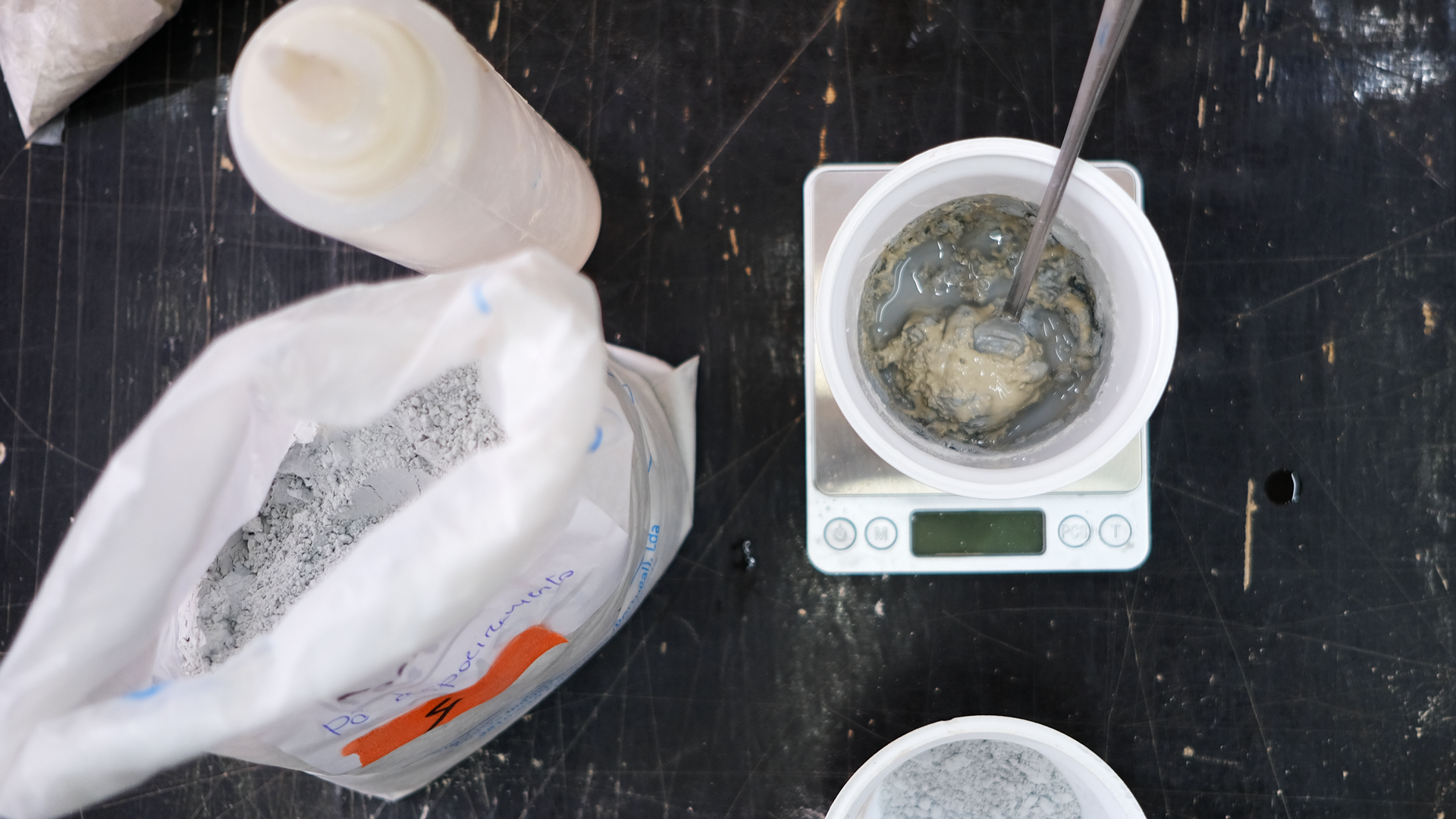

Production Process:

• waste collection

• Portioning: 100ml of ceramic paste with a composition of 30 % waste powder and 70% liquid raw material and additional 5-10% water

• slip casting mould

• drying phase

Firing:• bisque firing - low firing with temperature of 950 degrees

• second firing - high firing with temperature of 1200 degrees

Referencia:

1 - C4 - 001

1 (70%) - porcelain

C4 (30%) - dedusting powder

001 - Aveiro district