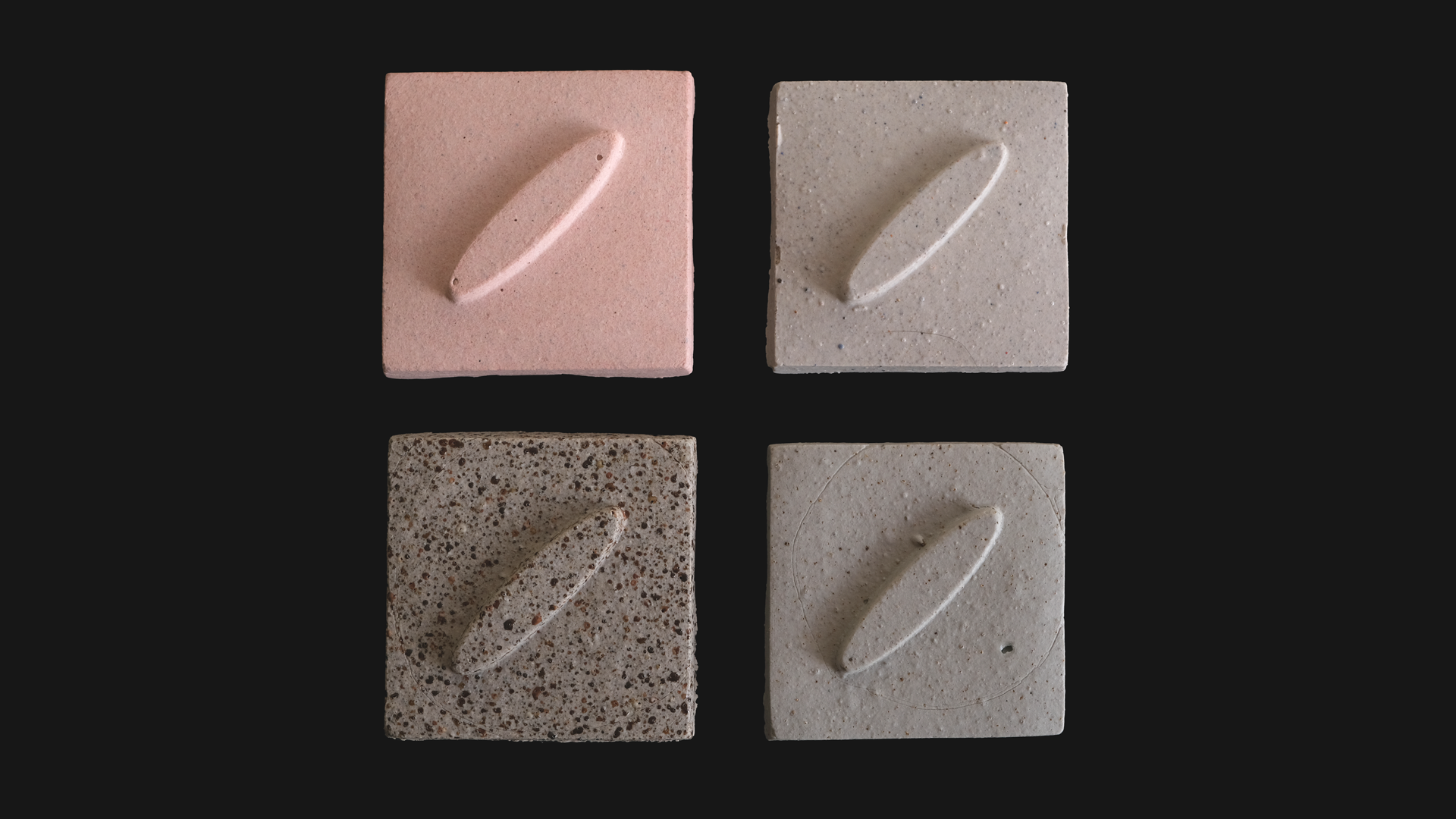

Experiment → 1-C5

1-C5

Output

70% porcelain with 30% sewage sludge waste aggregates.

This material samples contains sewage sludge, a mud-like residue resulting from wastewater treatment from the ceramic industry.

specs

Production Process:

• waste collection

• crumbling the wet sewage sludge parts into smaller parts and let it dry

• Portioning: 100ml of ceramic paste with a composition of 30 % waste powder and 70% liquid raw material and additional 5-10% water

• slip casting mould

• drying phase

Firing:

• bisque firing - low firing with temperature of 950 degrees

• second firing - high firing with temperature of 1200 degrees

Reference:

1 - C5 - 001

1 (70%) - porcelain

C5 (30%) - sewage sludge from water treatment

001 - Aveiro district