Experiment → 1-A5

1-A5

Output

Composition:

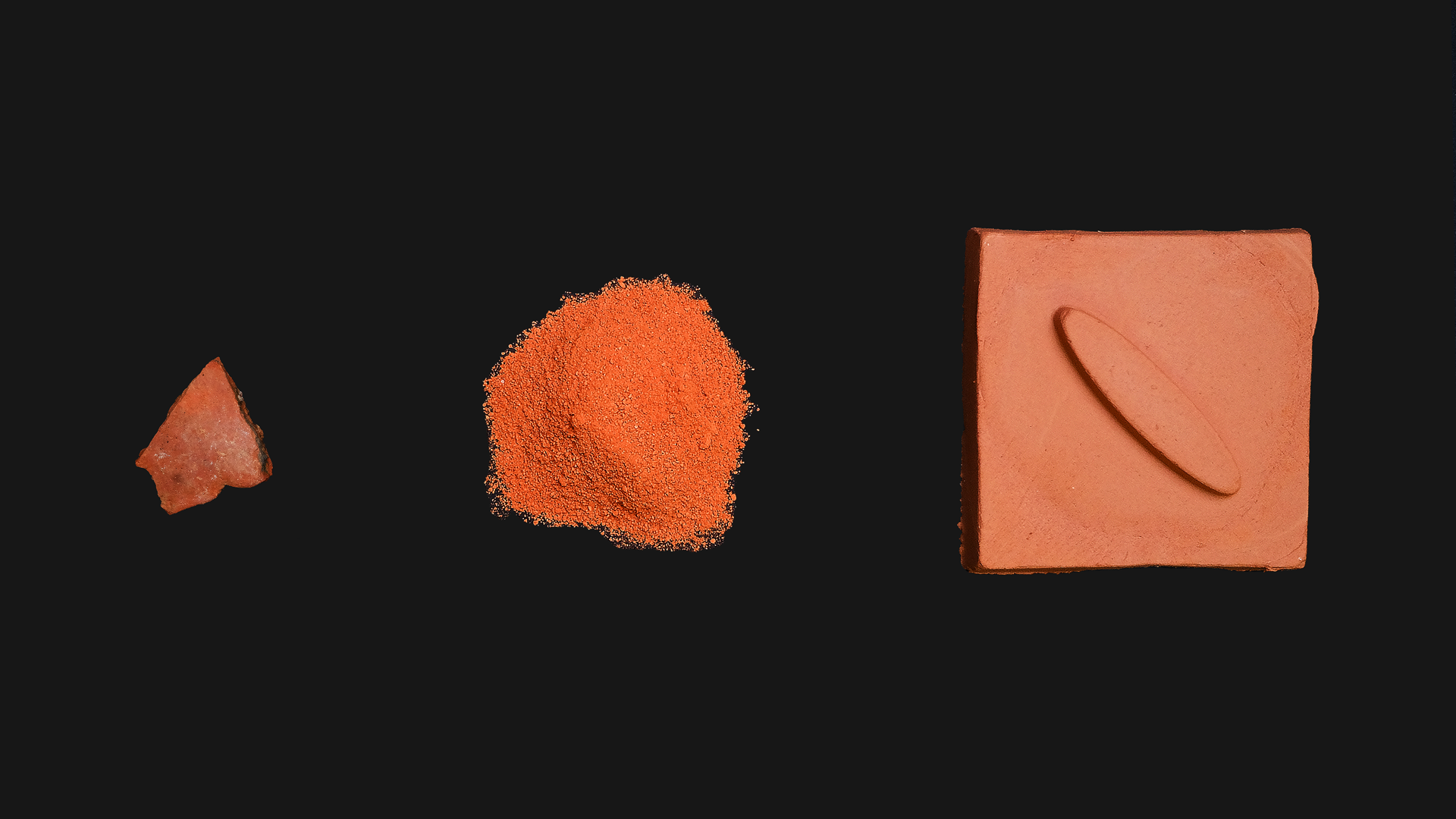

70% porcelain with 30% recycled brick waste aggregate.

This material samples contain a percentage of 30% of broken bricks found on a pill of rubbish on a construction side.

specs

Production Process:

• waste collection

• manual shredding process with a hammer to destroy the object into smaller pieces

• ceramic shredder (jaw crusher and than hammer mill machine) to get a fine waste ceramic powder at CICECO - Aveiro Institute of Materials

• Portioning: 100ml of ceramic paste with a composition of 30 % waste powder and 70% liquid raw material and additional 5-10% water

• slip casting mould

• drying phase

Firing:

• bisque firing - low firing with temperature of 950 degrees

• second firing - high firing with temperature of 1200 degrees

Referencia:

1 - A5 - 001

1 (70%) - porcelain

A5 (30%) - bricks

001 - Aveiro district

industries